1. Mawu Oyamba

This manual provides essential information for the safe and efficient operation, setup, and maintenance of your OMTech 90W CO2 Laser Engraver, Model SH-G570. Please read this manual thoroughly before operating the machine to ensure proper usage and to prevent damage or injury.

Chithunzi 1: Patsogolo view of the OMTech 90W CO2 Laser Engraver. This image shows the overall design of the machine, including the blue and gray casing, control panel area, and the base with wheels.

2. Zambiri Zachitetezo

Operating a laser engraver involves inherent risks. Adherence to safety protocols is paramount to prevent injury and ensure safe operation. This machine is a Laser Class 2 device with 0.874 mW output power.

- Chitetezo cha Maso: Never look directly into the laser beam. Always use appropriate laser safety glasses.

- Mpweya wabwino: Ensure adequate ventilation to remove smoke and fumes generated during engraving and cutting. The built-in air assist helps clear the workspace.

- Chitetezo Pamoto: Keep a fire extinguisher nearby. Do not leave the machine unattended during operation, especially when processing flammable materials.

- Zochita Zachitetezo Padzidzidzi: The flame-retardant viewing window allows for safe observation. The automatic cover interlock system halts laser operation if the lid is opened during a job.

- Kugwirizana kwazinthu: Chongolemba kapena kudula zinthu zomwe zavomerezedwa ndi ma laser a CO2. Pewani zinthu zomwe zimatulutsa utsi woopsa kapena zomwe zimawala kwambiri.

- Chitetezo cha Magetsi: Ensure the machine is properly grounded and connected to a suitable power supply. Do not operate with damaged cables or components.

3. Zamalonda Zathaview ndi Features

The OMTech 90W CO2 Laser Engraver (SH-G570) is designed for precise cutting and engraving across a variety of materials. Key features include:

- Mphamvu ya Laser: 90W CO2 laser tube, offering up to 1,000 hours of reliable use.

- Malo Ogwirira Ntchito: Spacious 28" x 20" (711 x 508 mm) workbed.

- Kudula Kuzama: Capable of cutting up to 0.4" (10 mm) deep in wood in a single pass.

- Liwiro Losema: Maximum engraving speed of 600 mm/s.

- Autofocus: Built-in autofocus feature for automatic setting of optimal focal distance.

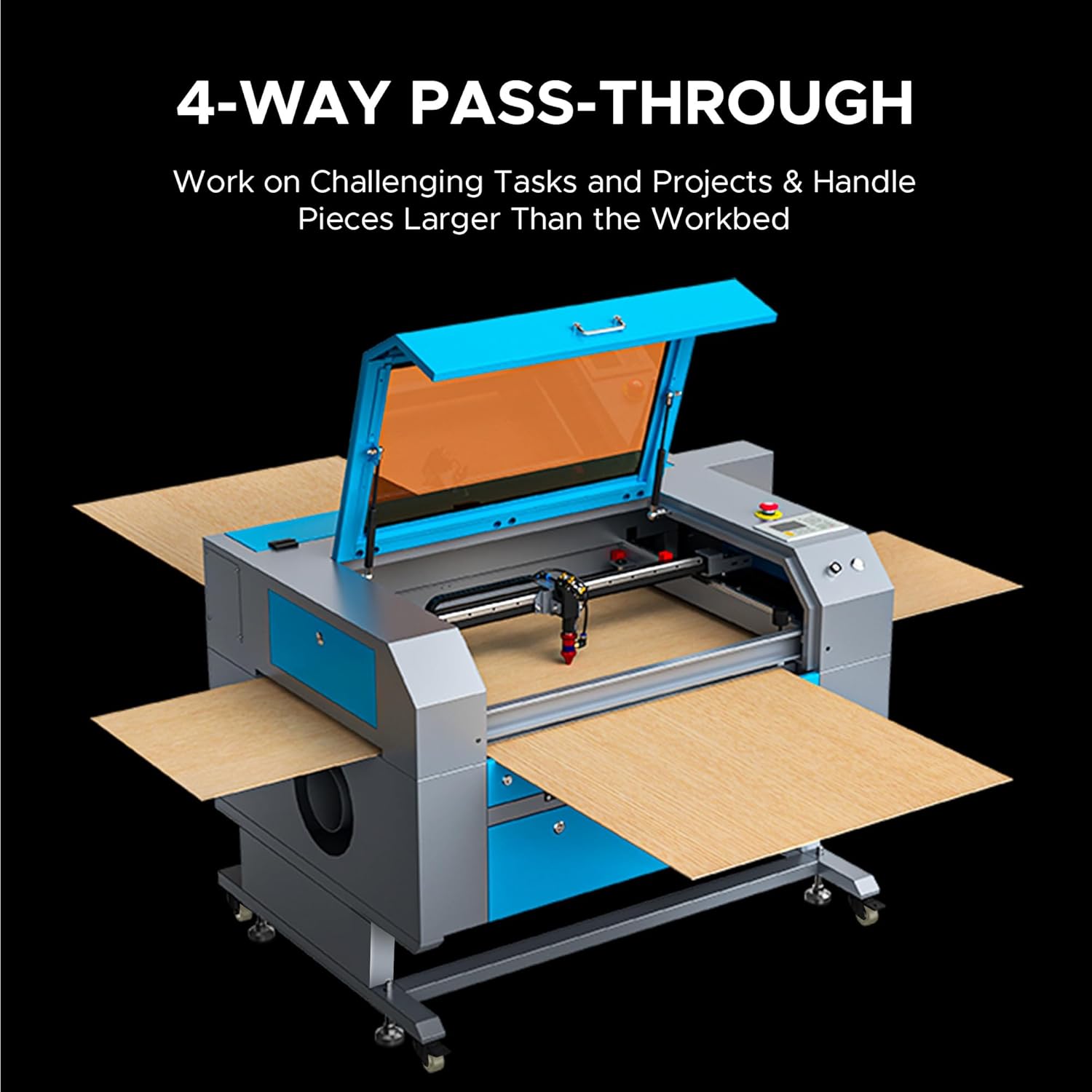

- Kudutsa: Four-way pass-through doors for processing larger materials.

- Workbeds: Includes both honeycomb and blade workbeds for versatile material support.

- Thandizo la Air: Integrated air assist system to reduce flare-ups and clear debris.

- Kugwirizana kwa Mapulogalamu: Compatible with RDWorks, LightBurn, CorelDRAW, and AutoCAD.

Figure 2: Infographic summarizing the key features and capabilities of the OMTech 90W CO2 Laser Engraver.

Chithunzi 3: Pafupi view illustrating the laser head cutting through 0.4 inches of basswood in a single pass, highlighting the machine's cutting capability.

Figure 4: Visual comparison of the OMTech engraver's 20x28 inch work area against a smaller standard size, demonstrating its larger processing capacity.

Figure 5: The digital control panel of the laser engraver, showcasing its compatibility with various design software including RDWorks, LightBurn, CorelDRAW, and AutoCAD.

Figure 6: The machine configured with its four-way pass-through doors open, illustrating how larger materials can be fed through the work area.

Figure 7: An animated illustration depicting the functionality of the built-in autofocus and air assist systems, showing how they optimize laser performance and clear debris.

4. Malangizo Kukhazikitsa

Proper setup is crucial for the safe and effective operation of your laser engraver. Follow these general steps:

- Kutulutsa: Carefully remove the machine and all accessories from the packaging. Inspect for any shipping damage.

- Kuyika: Place the engraver on a stable, level surface in a well-ventilated area, away from flammable materials. Ensure sufficient space around the machine for access and ventilation.

- Dongosolo Loziziritsira Madzi: Connect the provided water pump or chiller to the laser tube's inlet and outlet ports. Fill the reservoir with distilled water. Ensure water flows freely through the system before powering on the laser.

- Exhaust System: Connect the exhaust fan and ducting to the machine's exhaust port. Route the ducting to an outdoor vent or a suitable air filtration system to safely remove smoke and fumes.

- Kulumikiza Mphamvu: Connect the power cable to the machine and then to a grounded electrical outlet. Ensure the power supply matches the machine's requirements.

- Kuyika Mapulogalamu: Install the recommended laser control software (e.g., LightBurn, RDWorks) on your computer. Connect the engraver to your computer via USB or Ethernet.

- Initial Alignment (if necessary): Refer to the detailed software manual for initial laser path alignment procedures if required.

5. Malangizo Ogwiritsira Ntchito

Once the machine is set up, follow these steps for typical operation:

- Yatsani: Turn on the main power switch on the machine. Ensure the water cooling system is running.

- Kuyika Zinthu: Place your material on the workbed. Use the appropriate workbed (honeycomb for cutting, blade for engraving) for your task.

- Autofocus: Utilize the built-in autofocus function to set the correct focal distance for your material. This is typically done by pressing a dedicated button on the control panel or through the software.

- Kukonzekera Mapulogalamu: Open your design software, import or create your design. Set laser parameters (power, speed, frequency) according to the material type and desired effect.

- Job Transfer: Kusamutsa ntchito file to the laser engraver via the software.

- Frame Test: Use the 'Frame' function on the control panel to preview the job area on your material. Adjust material position if necessary.

- Yambani ntchito: Close the lid and press 'Start' on the control panel or in the software. Monitor the process closely.

- Kuyimitsa Mwadzidzi: In case of any malfunction or emergency, press the red emergency stop button immediately.

- Kuzimitsa Mphamvu: After the job is complete, power off the laser engraver and the water cooling system.

6. Kusamalira

Regular maintenance ensures optimal performance and extends the lifespan of your laser engraver.

- Lens and Mirror Cleaning: Regularly clean the laser lens and mirrors with specialized lens cleaning solution and wipes to maintain laser beam quality.

- Dongosolo Loziziritsira Madzi: Change the distilled water in the cooling system every 1-3 months, or more frequently with heavy use. Ensure the water chiller (if used) is functioning correctly.

- Workbed Cleaning: Clean the honeycomb and blade workbeds to remove debris and residue that can affect material placement and laser performance.

- Exhaust System: Inspect and clean the exhaust fan and ducting to ensure efficient removal of smoke and fumes.

- Rail and Belt Lubrication: Periodically lubricate the guide rails and check the tension of the drive belts to ensure smooth movement of the laser head.

- General Cleaning: Sungani mkati ndi kunja kwa makina mwaukhondo komanso opanda fumbi ndi zinyalala.

7. Mavuto

Chigawochi chikuwonetsa zovuta zomwe mungakumane nazo:

| Vuto | Chifukwa Chotheka | Yankho |

|---|---|---|

| Laser si kuwombera | Lid open, water flow error, power supply issue, laser tube failure | Ensure lid is closed, check water pump/chiller, verify power connections, contact support if tube is suspected faulty. |

| Zolemba zolakwika/zodula bwino | Incorrect focus, dirty lens/mirrors, incorrect power/speed settings, material issues | Perform autofocus, clean optics, adjust laser parameters, ensure material is flat and suitable. |

| Machine not connecting to computer | Loose cable, driver issue, incorrect software settings | Check USB/Ethernet cable, reinstall drivers, verify software communication settings. |

| Excessive smoke/fumes | Ineffective exhaust, material type | Check exhaust fan and ducting for blockages, ensure proper ventilation, use appropriate materials. |

8. Zofotokozera

Detailed technical specifications for the OMTech 90W CO2 Laser Engraver (SH-G570):

Figure 8: The OMTech 90W CO2 Laser Engraver shown in a workshop environment, with an overlay of its primary specifications.

- Mtundu: OmTech

- Nambala Yachitsanzo: SH-G570

- Mphamvu Yovotera: 90W

- Malo Ogwirira Ntchito: 28" x 20" (711 x 508 mm)

- Max. Liwiro Losema: 600 mm / s

- Max. Cutting Depth (Basswood, single pass): 0.4 mainchesi (10 mm)

- Makulidwe a Makina: 59.1 x 34.3 x 35.4 mainchesi (150.1 x 87.1 x 89.9 cm)

- Kulemera kwa chinthu: 258 mapaundi (117kg)

- Zofunika: Galvanized steel, Aluminium, Acrylic

- Kalasi ya Laser: 2

- Mphamvu Zotulutsa: 0.874 mW

- Pass-Through Doors: 4-njira

- Workbeds Included: Honeycomb and Blade

- Tsiku Loyamba Kupezeka: Juni 20, 2023

Material Application Chart

The following table outlines common materials and their compatibility with the engraver for both engraving and cutting:

Figure 9: A comprehensive table detailing the engraving and cutting compatibility of various materials with the OMTech laser engraver.

9. Chitsimikizo ndi Thandizo

For warranty information, technical support, or service inquiries, please refer to the official OMTech website or contact their customer service department. Keep your purchase receipt and model number (SH-G570) readily available when contacting support.

Zothandizira pa intaneti: Pitani ku Sitolo ya OMTech pa Amazon kuti mudziwe zambiri zamalonda ndi chithandizo.